Also known as “air barrier”, “air leakage”, “blower door” and “pressure” testing, air tightness testing is required by the US Army Corps of Engineers, NAVFAC and a growing number of municipalities, states and federal government agencies for all new conditioned buildings as well as for renovation projects totaling 25% or more of a building’s replacement value. HICAPS performs air tightness testing in accordance with ASTM E779-10 or ASTM E1827-11 and the USACE Air Leakage Test Protocol for Building Envelopes, Version 3 – May 11, 2012. Additionally, our technicians are certified and experienced with air leakage site detection using infrared thermography and smoke testing according to ASTM E1186. With a wealth of experience – hundreds of buildings tested – HICAPS can recommend proven solutions to issues diagnosed.

Why Tight? Why Test?

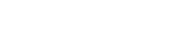

In most commercial and industrial buildings, outdoor air is introduced by design; however, uncontrolled air leakage across a building’s enclosure is responsible for a significant addition to space conditioning loads. The US Department of Energy estimates that 20 to 30 percent of heating and cooling costs in commercial and residential buildings are the result of air infiltration and exfiltration. An effective air barrier system reduces heating and cooling costs by minimizing this uncontrolled airflow.

More importantly, air barriers can significantly enhance building durability by preventing air-laden moisture from entering enclosure penetrations where it condenses on cooler surfaces resulting in premature material degradation and mold. Unintended airflow can result in over 200 times more moisture entering a building than vapor diffusion. The Air Barrier Association of America lists the following reasons for utilizing a continuous air barrier system.

- Reduces building enclosure moisture problems

- Improves indoor air quality

- Reduces building heating and cooling costs

- Improves acoustical isolation

- Isolates the indoor environment

- Results in sustainable, durable buildings

Fan-induced pressure testing is the only reliable, quantitative method of confirming that a building’s or a building zone’s air barrier is continuous and effective.

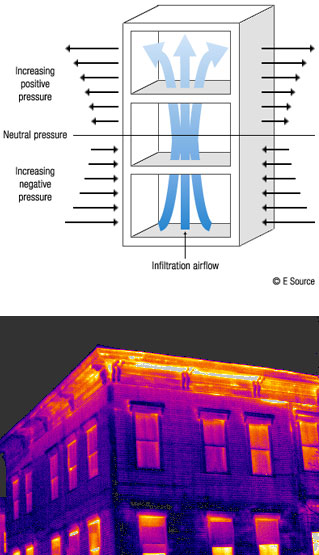

Infrared Thermography: Air tightness pressure testing and infrared thermography go hand-in-hand. While pressure testing provides quantitative information regarding how leaky a building is, IR thermography and other detection methods show us the leakage locations so we know where additional sealing measures are needed. That’s one of many reasons HICAPS employs certified thermographers with many years of experience performing infrared examinations of buildings.